Association of A.B.C. enthusiasts

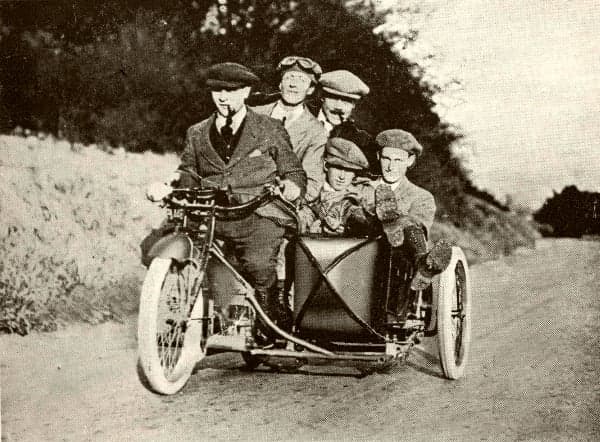

The Association of A.B.C. enthusiasts aims at finding and sharing information and parts about everything that is A.B.C., a company best known for its horizontally-opposed twin cylinder motorcycles but also involved in manufacturing of cars, scooters, aviation parts and engines for various purposes.

Few firms have been more ingenious and original than A.B.C. in their designs and this website aims at presenting the history and products of these inventors which were well ahead of their time.

Register for free to access the forum, advertise parts or ask for those A.B.C. missing bits.