- Posts: 178

ABC Cars, Aero engines and the Robin aeroplane

'Santa's Present'

- Paul

- Topic Author

- Offline

Less

More

4 years 1 month ago #1220

by Paul

'Santa's Present' was created by Paul

With reference to Giovanni's "Christmas" forum-column offering (ref. #1218),

WOTISIT??? that Santa is carrying...

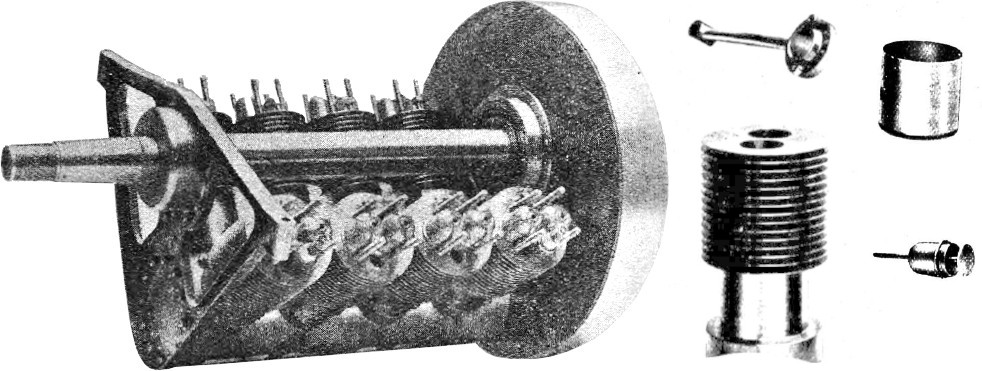

There's clearly a set of air-cooled cylinders in conventional Vee-8 formation, but the thing at their bases is far too small to be any kind of crankcase. (Santa could never have lifted such an engine with a crankshaft in it).

There appears to be a sparking plug in the RH rear cylinder. And what are the "caps" atop the cylinders?

Can it all be part of a test-rig for a matching set of cylinders? A hydraulic pressure test perhaps?

Your ideas, please!

(Giovanni will reward the winner with a free year's subscription to the website!)

WOTISIT??? that Santa is carrying...

There's clearly a set of air-cooled cylinders in conventional Vee-8 formation, but the thing at their bases is far too small to be any kind of crankcase. (Santa could never have lifted such an engine with a crankshaft in it).

There appears to be a sparking plug in the RH rear cylinder. And what are the "caps" atop the cylinders?

Can it all be part of a test-rig for a matching set of cylinders? A hydraulic pressure test perhaps?

Your ideas, please!

(Giovanni will reward the winner with a free year's subscription to the website!)

Please Log in or Create an account to join the conversation.

- Roger

- Offline

Less

More

- Posts: 54

4 years 1 month ago #1221

by Roger

Replied by Roger on topic 'Santa's Present'

It is of course Partridge but not in a pear tree so it must be the day before the First Day of Christmas.

Presumably he was rehearsing the eight day with one cylinder each day so it would have ended up with a V-24.

The single spark plug was to cut down on the weight as it was an aero engine and that is one reason that it never flew - another example of Granville Bradshaw's genius.

Presumably he was rehearsing the eight day with one cylinder each day so it would have ended up with a V-24.

The single spark plug was to cut down on the weight as it was an aero engine and that is one reason that it never flew - another example of Granville Bradshaw's genius.

Please Log in or Create an account to join the conversation.

- gioorl

-

- Offline

Less

More

- Posts: 152

4 years 1 month ago - 4 years 1 month ago #1222

by gioorl

Replied by gioorl on topic 'Santa's Present'

Last edit: 4 years 1 month ago by gioorl.

Please Log in or Create an account to join the conversation.

- Dabney

- Offline

Less

More

- Posts: 96

4 years 1 month ago #1223

by Dabney

Replied by Dabney on topic 'Santa's Present'

In the Christmas spirit, I will guess at what is this present. The engine is designed for a propeller for use on an aircraft or airship, as it has no flywheel. Based on the size of the person and assuming a square bore/stroke, it has a capacity of about 2- 3 litres. The reduction gear on the end of the engine is about 5 to 1. The engine being ABC is likely to be a high rpm engine. Running at 3,400rpm it could take a direct propeller. Adding the reduction gear, it suggest a large diameter propeller - hence maybe a airship.

How the valves / induction would operate I have no idea. The studs about the heads I can only assume would be designed to house the valve operating mechanism? The exhaust I can only assume would have been directly from the cylinder. Interestingly the Le Rhone rotary of the period only used one spark plug which would have been driven by a HT magneto.

best wishes Ian

How the valves / induction would operate I have no idea. The studs about the heads I can only assume would be designed to house the valve operating mechanism? The exhaust I can only assume would have been directly from the cylinder. Interestingly the Le Rhone rotary of the period only used one spark plug which would have been driven by a HT magneto.

best wishes Ian

Please Log in or Create an account to join the conversation.

- Paul

- Topic Author

- Offline

Less

More

- Posts: 178

4 years 1 month ago #1225

by Paul

Replied by Paul on topic 'Santa's Present'

...My turn for another guess.

(I think that Giovanni is holding out on us a bit...the bearded gent could be Bobbo Natale, to start with).

A late-teens Magnat-Debon had similar blind cylinders, with screw-in valve-pots.

I agree with Ian about the rockers etc., but not his stroke: that "crankcase" is too small to be serious.

Come on Giovanni, we're ready to hear the real answer!

(I think that Giovanni is holding out on us a bit...the bearded gent could be Bobbo Natale, to start with).

A late-teens Magnat-Debon had similar blind cylinders, with screw-in valve-pots.

I agree with Ian about the rockers etc., but not his stroke: that "crankcase" is too small to be serious.

Come on Giovanni, we're ready to hear the real answer!

Please Log in or Create an account to join the conversation.

- gioorl

-

- Offline

Less

More

- Posts: 152

4 years 1 month ago #1226

by gioorl

Replied by gioorl on topic 'Santa's Present'

Careful what you wish for this Xmas… any answer might raise more questions than you can imagine.

By 1913, A.B.C. had been in business for 2.5 years and was still struggling to make its water-cooled engines work as desired. Although these were advertised as ready for sale, we should really consider them as early prototypes and only the 4 cylinder straight model proved to be reliable. Yet, only two of them were ever made.

Refining designs for production was clearly boring and not very creative so they decided to focus on development only and outsource production of all their aviation engines to Messers Armstrong-Withworth of Newcastle-on-Tyne.

The comments which came back from the Withworth employees are best left for another post but, in any case, Bradshaw was left with a lot of time to work on developing new designs for both aero and motorcycle engines.

Santa's present is the first air-cooled aero engine designed by Bradshaw as a result of the experience gained with Les Bailey in the second half of 1912.

I can only imagine Bradshaw did not enjoy Christmas in 1912 … Bailey took his record on 17/12/12 and during the first week in January '13 Bradshaw was already displaying both the very first A.B.C. motorcycle engine and this experimental V8.

The magazine The Aero described the V8 as follows in the January 1913 edition:

"Whenever it is our good fortune to pay a visit to that most fascinating of flying grounds —Brooklands— we always make a point of calling at the works of the All-British (Engine) Co., where we may feel sure of finding something of unusual interest in the nature of experimental work connected with aeroplane engines.

At the present time there is nearing completion an engine the like of which we have never seen before. In the first place it is designed to run at a normal speed of about 4,200 r.p.m. It is provided with eight steel cylinders of 2 1/2 in. bore and 2 1/4 in. stroke, set upon a tubular steel crank case in the 90° Vee manner.

On the end of the crankshaft is mounted a spur gear which drives a large reduction gear having a ratio of 6 to 1. The larger gear wheel is carried 011 a stiff shaft running in ball journal and thrust bearings. This shaft passes between the cylinders, and at its end is provided with a taper for the attachment of the

propeller boss. The propeller is, therefore, rotated at one-sixth the speed of the engine. This propeller-shaft also serves as a camshaft, and upon it are mounted cams which operate rocking arms making contact with the stems of the overhead valves, there being no tappets. Owing to the 6 to 1 reduction in speed on this main shaft, three cams have to be cut on each cam blank to operate one valve.

The whole engine is made of special steels, with the exception of the pistons. The cylinders are set upon the crank case in the staggered fashion, so that there is no overhang in the bearings of the connecting rods.

[...] the connecting rods are not held on by bolts passing through the big end parallel to the length of the rod, but by hollow pins passing through hinges in the rod end and cap at right angles to the long axis. These hollow pins are locked in position by means of copper tubes placed through them and expanded out

at the ends. There are no bolts, nuts, split pins, or spring washers inside the engine at all, and therefore nothing to shake loose from vibration.

This engine is expected to develop about 50 h.p. for a weight of 112 lbs.

[...] The crankshaft runs upoh four ball bearings, one at the front end, one in the middle, i.e., between the centre pair of cylinders, one at the back end against the gear wheel, and one in the cover of the case on the other side of the gear wheel There is, therefore, no bearing between each throw of the crank,

but between alternate throws. The centre ball bearing is slipped over the shaft and held on to a split sleeve by a steel locking device without the aid of bolts, nuts, or split pins.

[..] The valves themselves are carried in cages held to the top of the cylinders by means of bolts and dogs. The brackets carrying the rocking arms are also bolted to the cylinder heads.

Two magnetos are to be fitted running at engine speed and driven by a chain at the back of the engine. It is proposed to fit a small centrifugal air pump running at engine speed if the engine does not keep sufficiently cool with the aid of the propeller draught and baffle plates.

Splash lubrication is to be employed. This may be a debatable point, but, on the other hanc we have actually seen a little two-cylinder horizontally opposed engine fitted by the All-British Engine Co. with special steel cylinders similar to those employed on the aeroplane engine, but about 15% smaller, turning round at the rate of about 6,500 r.p.m. without, apparently any difficulty whatever."

It's clear from the pictures that the engine in “Santa’s” arms was not complete but there is also no known record of it ever being fitted to an aeroplane or even being completed. I can only imagine this was the beginning and the end of that design.

Still, quite a unique Christmas present!

By 1913, A.B.C. had been in business for 2.5 years and was still struggling to make its water-cooled engines work as desired. Although these were advertised as ready for sale, we should really consider them as early prototypes and only the 4 cylinder straight model proved to be reliable. Yet, only two of them were ever made.

Refining designs for production was clearly boring and not very creative so they decided to focus on development only and outsource production of all their aviation engines to Messers Armstrong-Withworth of Newcastle-on-Tyne.

The comments which came back from the Withworth employees are best left for another post but, in any case, Bradshaw was left with a lot of time to work on developing new designs for both aero and motorcycle engines.

Santa's present is the first air-cooled aero engine designed by Bradshaw as a result of the experience gained with Les Bailey in the second half of 1912.

I can only imagine Bradshaw did not enjoy Christmas in 1912 … Bailey took his record on 17/12/12 and during the first week in January '13 Bradshaw was already displaying both the very first A.B.C. motorcycle engine and this experimental V8.

The magazine The Aero described the V8 as follows in the January 1913 edition:

"Whenever it is our good fortune to pay a visit to that most fascinating of flying grounds —Brooklands— we always make a point of calling at the works of the All-British (Engine) Co., where we may feel sure of finding something of unusual interest in the nature of experimental work connected with aeroplane engines.

At the present time there is nearing completion an engine the like of which we have never seen before. In the first place it is designed to run at a normal speed of about 4,200 r.p.m. It is provided with eight steel cylinders of 2 1/2 in. bore and 2 1/4 in. stroke, set upon a tubular steel crank case in the 90° Vee manner.

On the end of the crankshaft is mounted a spur gear which drives a large reduction gear having a ratio of 6 to 1. The larger gear wheel is carried 011 a stiff shaft running in ball journal and thrust bearings. This shaft passes between the cylinders, and at its end is provided with a taper for the attachment of the

propeller boss. The propeller is, therefore, rotated at one-sixth the speed of the engine. This propeller-shaft also serves as a camshaft, and upon it are mounted cams which operate rocking arms making contact with the stems of the overhead valves, there being no tappets. Owing to the 6 to 1 reduction in speed on this main shaft, three cams have to be cut on each cam blank to operate one valve.

The whole engine is made of special steels, with the exception of the pistons. The cylinders are set upon the crank case in the staggered fashion, so that there is no overhang in the bearings of the connecting rods.

[...] the connecting rods are not held on by bolts passing through the big end parallel to the length of the rod, but by hollow pins passing through hinges in the rod end and cap at right angles to the long axis. These hollow pins are locked in position by means of copper tubes placed through them and expanded out

at the ends. There are no bolts, nuts, split pins, or spring washers inside the engine at all, and therefore nothing to shake loose from vibration.

This engine is expected to develop about 50 h.p. for a weight of 112 lbs.

[...] The crankshaft runs upoh four ball bearings, one at the front end, one in the middle, i.e., between the centre pair of cylinders, one at the back end against the gear wheel, and one in the cover of the case on the other side of the gear wheel There is, therefore, no bearing between each throw of the crank,

but between alternate throws. The centre ball bearing is slipped over the shaft and held on to a split sleeve by a steel locking device without the aid of bolts, nuts, or split pins.

[..] The valves themselves are carried in cages held to the top of the cylinders by means of bolts and dogs. The brackets carrying the rocking arms are also bolted to the cylinder heads.

Two magnetos are to be fitted running at engine speed and driven by a chain at the back of the engine. It is proposed to fit a small centrifugal air pump running at engine speed if the engine does not keep sufficiently cool with the aid of the propeller draught and baffle plates.

Splash lubrication is to be employed. This may be a debatable point, but, on the other hanc we have actually seen a little two-cylinder horizontally opposed engine fitted by the All-British Engine Co. with special steel cylinders similar to those employed on the aeroplane engine, but about 15% smaller, turning round at the rate of about 6,500 r.p.m. without, apparently any difficulty whatever."

It's clear from the pictures that the engine in “Santa’s” arms was not complete but there is also no known record of it ever being fitted to an aeroplane or even being completed. I can only imagine this was the beginning and the end of that design.

Still, quite a unique Christmas present!

Please Log in or Create an account to join the conversation.