- Posts: 96

ABC prototype letter January 2nd 1919

- Dabney

- Topic Author

- Offline

Less

More

9 years 4 weeks ago - 9 years 4 weeks ago #297

by Dabney

ABC prototype letter January 2nd 1919 was created by Dabney

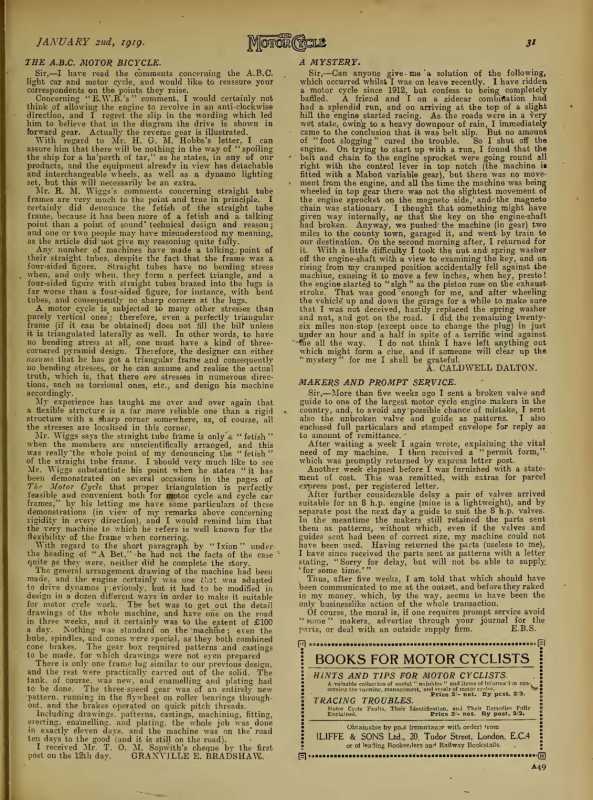

I came across what I found was this interesting letter from Granville Bradshaw in The MotorCycle dated January 2nd 1919 on the ABC Sopwith prototype and have attached it for those who may not of seen it. It is somewhat fitting that it was published 98 years ago virtually to the day. Happy New Year to all with interest in ABC's

Apologies about the quality - the site has restricted the size of the pdf I can load ; hence the image copy

Apologies about the quality - the site has restricted the size of the pdf I can load ; hence the image copy

Last edit: 9 years 4 weeks ago by Dabney.

Please Log in or Create an account to join the conversation.

- degraaff

- Offline

Less

More

- Posts: 76

9 years 4 weeks ago #298

by degraaff

Replied by degraaff on topic ABC prototype letter January 2nd 1919

where is the letter?

Please Log in or Create an account to join the conversation.

- Dabney

- Topic Author

- Offline

Less

More

- Posts: 96

9 years 4 weeks ago - 9 years 4 weeks ago #299

by Dabney

Replied by Dabney on topic ABC prototype letter January 2nd 1919

Also just attached file

Last edit: 9 years 4 weeks ago by Dabney.

Please Log in or Create an account to join the conversation.

- gioorl

-

- Offline

Less

More

- Posts: 146

7 years 9 months ago #400

by gioorl

Replied by gioorl on topic ABC prototype letter January 2nd 1919

I was struggling to read the article in the picture which was attached to the previous post so I did some digging and typed it out for better reading.

I need to find Ixion's article which prompted the last reply...

THE A.B.C. MOTOR BICYCLE.

Sir, I have read the comments concerning the A.B.C. light car and motor cycle, and would like to reassure your correspondents on the points they raise.

Concerning "E.W.B.'s" comment, I would certainly not think of allowing the engine to revolve in an anti-clockwise direction, and I regret the slip in the wording which led him to believe that in the diagram the drive is shown in forward gear. Actually the reverse gear is illustrated.

With regard to Mr. H. G. M. Hobbs's letter, I can assure him that there will be nothing in the way of "spoiling the ship for a ha'porth of tar," as he states, in any of our products, and the equipment already in view has detachable and interchangeable wheels, as well as a dynamo lighting set, but this will necessarily be an extra.

Mr. R. M. Wiggs's comments concerning straight tube frames are very much to the point and true in principle. I certainly did denounce the fetish of the straight tube frame, because it has been more of a fetish and a talking point than a point of sound technical design and reason; and one or two people may have misunderstood my meaning, as the article did not give my reasoning quite fully.

Any number of machines have made a talking—point of their straight tubes, despite the fact that the frame was a four-sided figure. Straight tubes have no bending stress when, and only when, they form a perfect triangle, and a four-sided figure with straight tubes brazed into the lugs is far worse than a four-sided figure, for instance, with bent tubes, and consequently no sharp corners at the lugs.

A motor cycle is subjected to many other stresses than purely vertical ones; therefore, even a perfectly triangular frame (if it can be obtained) does not fill the bill unless it is triangulated laterally as well. In other words, to have no bending stress at all, one must have a kind of three-cornered pyramid design. Therefore, the designer can either assume that he has got a triangular frame and consequently no bending stresses, or he can assume and realise the actual truth, which is, that there are stresses in numerous directions, such as torsional ones, etc., and design his machine accordingly.

My experience has taught me over and over again that a flexible structure is a far more reliable one than a rigid structure with a corner somewhere, as, of course, all the stresses are localised in this corner.

Mr. Wiggs says the straight tube frame is only a "fetish when the members are unscientifically arranged, and this was really the whole point of my denouncing the "fetish" of the straight tube frame. I should very much like to see Mr. Wiggs substantiate his point when he states "it has been demonstrated on several occasions in the pages of The Motor Cycle that proper triangulation is perfectly feasible and convenient both for cycle and cycle car frames," by his letting me have some particulars of these demonstrations (in view of my remarks above concerning rigidity in every direction), and I would remind him that the very machine to which he refers is well known for the flexibility of the frame when cornering.

With regard to the short paragraph by "Ixion" under the heading of "A Bet," he had not the facts of the case quite as they were, neither did he complete the story.

The general arrangement drawing of the machine had been made and the engine certainly was one that was adapted to drive dynamos previously, but it had to be modified in design in a dozen different ways in order to make it suitable for motor cycle work. The bet was to get out the detail drawings of the whole machine, and have one on the road in three weeks, and it certainly was to the extent of £100 a day. Nothing was standard on the machine; even the hubs, spindles, and cones were special, as they both combined cone brakes. The gear box required patterns and castings to be made, for which drawings were not even prepared.

There is only one frame lug similar to our previous design, and the rest were practically carved out of the solid. The tank, of course, was new, and enamelling and plating had to be done. The three-speed gear was of an entirely new pattern, running in the flywheel on roller bearings throughout, and the brakes operated on quick pitch threads.

Including drawings, patterns, castings, machining, fitting, erecting, enamelling, and plating, the whole job was done in exactly eleven days, and the machine was on the road ten days to the good (and it is still on the road).

I received Mr. T.O.M. Sopwith's cheque by the first post on the 12th day.

GRANVILLE E. BRADSHAW.

I need to find Ixion's article which prompted the last reply...

THE A.B.C. MOTOR BICYCLE.

Sir, I have read the comments concerning the A.B.C. light car and motor cycle, and would like to reassure your correspondents on the points they raise.

Concerning "E.W.B.'s" comment, I would certainly not think of allowing the engine to revolve in an anti-clockwise direction, and I regret the slip in the wording which led him to believe that in the diagram the drive is shown in forward gear. Actually the reverse gear is illustrated.

With regard to Mr. H. G. M. Hobbs's letter, I can assure him that there will be nothing in the way of "spoiling the ship for a ha'porth of tar," as he states, in any of our products, and the equipment already in view has detachable and interchangeable wheels, as well as a dynamo lighting set, but this will necessarily be an extra.

Mr. R. M. Wiggs's comments concerning straight tube frames are very much to the point and true in principle. I certainly did denounce the fetish of the straight tube frame, because it has been more of a fetish and a talking point than a point of sound technical design and reason; and one or two people may have misunderstood my meaning, as the article did not give my reasoning quite fully.

Any number of machines have made a talking—point of their straight tubes, despite the fact that the frame was a four-sided figure. Straight tubes have no bending stress when, and only when, they form a perfect triangle, and a four-sided figure with straight tubes brazed into the lugs is far worse than a four-sided figure, for instance, with bent tubes, and consequently no sharp corners at the lugs.

A motor cycle is subjected to many other stresses than purely vertical ones; therefore, even a perfectly triangular frame (if it can be obtained) does not fill the bill unless it is triangulated laterally as well. In other words, to have no bending stress at all, one must have a kind of three-cornered pyramid design. Therefore, the designer can either assume that he has got a triangular frame and consequently no bending stresses, or he can assume and realise the actual truth, which is, that there are stresses in numerous directions, such as torsional ones, etc., and design his machine accordingly.

My experience has taught me over and over again that a flexible structure is a far more reliable one than a rigid structure with a corner somewhere, as, of course, all the stresses are localised in this corner.

Mr. Wiggs says the straight tube frame is only a "fetish when the members are unscientifically arranged, and this was really the whole point of my denouncing the "fetish" of the straight tube frame. I should very much like to see Mr. Wiggs substantiate his point when he states "it has been demonstrated on several occasions in the pages of The Motor Cycle that proper triangulation is perfectly feasible and convenient both for cycle and cycle car frames," by his letting me have some particulars of these demonstrations (in view of my remarks above concerning rigidity in every direction), and I would remind him that the very machine to which he refers is well known for the flexibility of the frame when cornering.

With regard to the short paragraph by "Ixion" under the heading of "A Bet," he had not the facts of the case quite as they were, neither did he complete the story.

The general arrangement drawing of the machine had been made and the engine certainly was one that was adapted to drive dynamos previously, but it had to be modified in design in a dozen different ways in order to make it suitable for motor cycle work. The bet was to get out the detail drawings of the whole machine, and have one on the road in three weeks, and it certainly was to the extent of £100 a day. Nothing was standard on the machine; even the hubs, spindles, and cones were special, as they both combined cone brakes. The gear box required patterns and castings to be made, for which drawings were not even prepared.

There is only one frame lug similar to our previous design, and the rest were practically carved out of the solid. The tank, of course, was new, and enamelling and plating had to be done. The three-speed gear was of an entirely new pattern, running in the flywheel on roller bearings throughout, and the brakes operated on quick pitch threads.

Including drawings, patterns, castings, machining, fitting, erecting, enamelling, and plating, the whole job was done in exactly eleven days, and the machine was on the road ten days to the good (and it is still on the road).

I received Mr. T.O.M. Sopwith's cheque by the first post on the 12th day.

GRANVILLE E. BRADSHAW.

The MotorCycle, January 2nd 1919

The following user(s) said Thank You: skootamota, johnemanuel, T. Baxter

Please Log in or Create an account to join the conversation.

- gioorl

-

- Offline

Less

More

- Posts: 146

7 years 8 months ago #404

by gioorl

Replied by gioorl on topic ABC prototype letter January 2nd 1919

Here's Ixion's note in December 1918 which prompted Bradshaw's letter

A Bet. A GOOD yarn is going the rounds anent the new A.B.C. bicycle. The bottom dropped out of the war so abruptly that Mr. Bradshaw — like all other motor engineers — was. caught napping. He had his engine ready, for it had been a "munition for four years past, but his brain had been switched off motor cycle gears, frames, etc., for many a long day. The managing director of the firm who had previously covenanted to manufacture the post-war A.B.C. bicycles came round at 60 m.p.h. : How soon can you have the drawings of that bicycle ready? Mr. Bradshaw defined the necessary preliminary tests; when these were agreed upon, he

estimated the 'bus would be ready to go into production in three weeks. "Impossible!" "What will you bet?" "£1oo a day premium if early: same penalty if late!" "Done!"

This was the result of a series of announcements recently made by Bradshaw and T.O.M Sopwith (1918) about the new revolutionary A.B.C. motorcycle.

More details can be found here

The A.B.C. Post-war Programme

and here

Luncheon at the Sopwith Aviation Co.'s works at Kingston-on-Thames

A Bet. A GOOD yarn is going the rounds anent the new A.B.C. bicycle. The bottom dropped out of the war so abruptly that Mr. Bradshaw — like all other motor engineers — was. caught napping. He had his engine ready, for it had been a "munition for four years past, but his brain had been switched off motor cycle gears, frames, etc., for many a long day. The managing director of the firm who had previously covenanted to manufacture the post-war A.B.C. bicycles came round at 60 m.p.h. : How soon can you have the drawings of that bicycle ready? Mr. Bradshaw defined the necessary preliminary tests; when these were agreed upon, he

estimated the 'bus would be ready to go into production in three weeks. "Impossible!" "What will you bet?" "£1oo a day premium if early: same penalty if late!" "Done!"

The MotorCycle, December 19th, 1918

This was the result of a series of announcements recently made by Bradshaw and T.O.M Sopwith (1918) about the new revolutionary A.B.C. motorcycle.

More details can be found here

The A.B.C. Post-war Programme

and here

Luncheon at the Sopwith Aviation Co.'s works at Kingston-on-Thames

The following user(s) said Thank You: T. Baxter

Please Log in or Create an account to join the conversation.