This poorly-conceived device has been the subject of more complaint, disillusionment and impotent fury than any other part of the machine.

The following notes aren't guaranteed to dispel much of this, but might help, just a little.

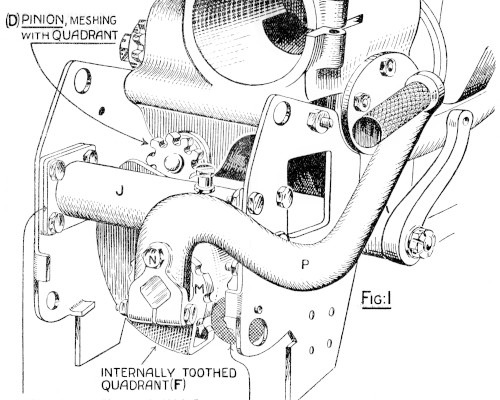

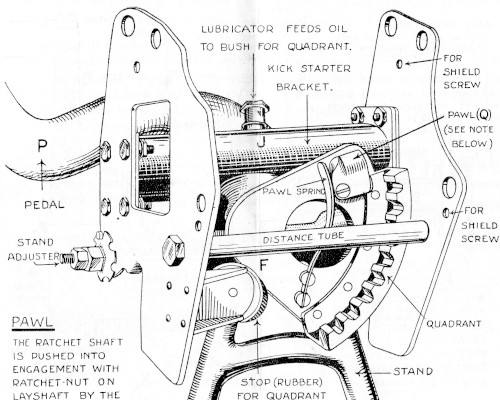

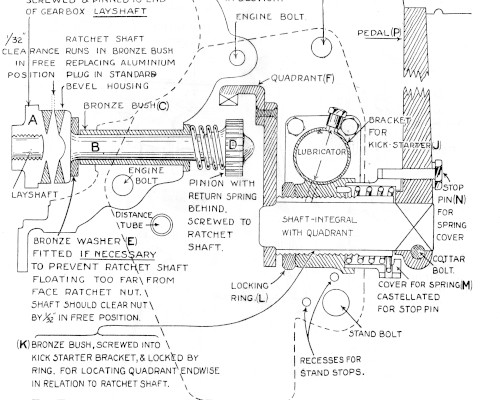

How the Kickstarter was Intended to Work (With Recourse to the Attached Illustrations):-

Depression of the footpedal caused the inverted teeth of the quadrant to engage the teeth of the ratchet shaft's pinion, whilst almost simultaneously, the pawl on the quadrant contacted the central nose of this pinion: these two events (a) initiated rotation of the ratchet shaft, and (b) shifted the face-ratchet on this shaft into engagement with its counterpart at the rear of the gearbox layshaft.

Somewhere before half-stroke of the footpedal, the tail end of the pawl cleared the pinion's nose. The ratchet shaft's return spring wasn't strong enough to overcome the 'transferred friction' between the engaged teeth of the face-ratchets as they turned, and the ratchet teeth would remain in mesh until the end of the footpedal's stroke.

If the engine fired, of course, the face-ratchets would cause immediate ratchet shaft retraction.*

On the return stroke of the footpedal, the quadrant's pawl would be swivelled backwards, slide round the pinion's nose, and then be snapped back into its initial position by a simple (leaf) spring.

So much for the theory....

Although the component parts of the device were sturdy enough, a 'system' problem was the length of the tolerance-chain between the teeth of the pinion and the quadrant: inadequate meshing was not uncommon.

Meshing-area was at about "11 o'clock". (i) Lateral adjustment of the components was very limited, with packing plates, and (ii) Vertical adjustment was zero! About the easiest way forward was to provide vertical adjustment, by elongating downwards, the 8-off 1/4" holes of the main-structure clamping bolts in the side-plates...

The other common problem involved the premature disengagement of the ratchet, at less than half-stroke: usually caused by less than full engagement of the ratchet-faces. An adjustment facility for this was provided, see Fig. 3, "bronze bush/locking ring", noting however that these could only be worked with "C" spanners.

* Note here a potentially catastrophic design fault: if the engine fired before the pawl cleared the pinion's nose, serious damage could result.