Introduction

The readers of this website should be familiar with the beginnings of the ABC company in 1910. Ronald Louis Charteris and Walter Lawson Adams formed the W.L. Aero Engine Company Limited which was later renamed to The All British (Engine) Company Ltd.

Not many however are aware of who Walter Lawson Adams was and what he achieved in his life. Roger Bird investigated the history of this virtually unknown British motoring pioneer who was involved in the development of combustion engines since the end of the XIX century.

Early Life

Walter Lawson Adams was born in Norwich in the second quarter of 1874 and his father, Lawson Adams was a miller.

In 1894 he married Susan White née Mardlin, a widow, born in 1871. At the time of marriage, he gave his age as 25, two years younger than his wife although his wife is shown as five years older in the 1901 census where they claimed to be 30 and 35. Ten years later, the 1911 census shows that Walter had aged seven years and his wife just five. The most likely explanation for these differences is that Walter claimed to be 25 so that he could marry without his parents’ permission and that the 1911 census gives their correct ages; 37 for Walter and 40 for Susie. When they were married at the Bedford Registry Office, they both gave an address in Houghton Road, Bedford and after their marriage they lived in Sweet Briar Villa, Houghton Road which was Walter’s address.

Houghton Road is adjacent to the Britannia Iron works who produced steam engines and it is likely that he was an apprentice at the works. In 1896 Britannia produced a V-4cylinder Pennington designed engine and it is tempting to think that Walter was involved in that development but they had moved to Lowestoft before that date probably when Walter was 21 in 1895 and able to set up his own business in the cycle trade. His cycle repairer and agency business were at 52, High Street, Lowestoft but he was declared bankrupt in late November 1896 with liabilities of £302. This was not a trivial sum and it would have taken a number of years to repay that amount plus interest when a good wage would have been £2 a week. Walter was able to resume his business to repay the debt and set himself up as a Cycle Agent and Manufacturer at 319 London Road, Lowestoft and he started to show his inventive genius.

He applied for his first patent in December 1897 which was granted[i] the following December and it could have revolutionised the assembly of cycle frames by small manufacturers as it used wedges to secure tubes to lugs avoiding the need to pin and braze the joints. His second patent[ii] probably derived from his experience with bicycle tubes as it was for a valve in a football bladder. As this was a time of significant developments in the automotive world where Harry Lawson was attempting to create a monopoly there would have been a ready market for both of these inventions which would have allowed Walter to discharge his bankruptcy.

Freed from debt Walter was able to expand his interests to include machines driven by internal combustion engines with the purchase of a Beeston tricycle, copy of the De Dion Bouton tricycle but with the rather curious replacement of the excellent spark ignition with the by then outdated hot tube type. S. F. Edge who marketed the Beeston claimed that it only required petrol to run as spark ignition also required a battery that could run flat; this was before the magneto was available.

In what was one of the first motor races The Autocar reported on August 26th 1899, a five-mile motor tricycle race organised by the Lowestoft and Kirkley Cycling and Athletic Club in which Mr. James Last, on a De Dion et Bouton raced against Mr. W. L. Adams, on a Beeston motor. Adams had half a lap start out of the fifteen indicating that his was a smaller 1¼ horsepower machine than Last’s who was a minute ahead at the end of the race covering the five miles at 20.7 mph.

Walter also appears to have been involved with Aster at that time as The Autocar of 12th August 1899 started an exchange with Charles Sangster of Ariel who questioned the accuracy of the horsepower rating for the Aster engines. Walter claimed that Aster used dynamo testing which was superior to brake or indicator diagram readings and that “anyone purchasing an Aster motor can rely upon it developing two and a quarter horse-power before it is allowed to leave the works”. The exchange concluded with a letter from Walter in the 21st October edition when he largely agreed with Sangster’s approach of testing all engines but suggested that certificates should be issued with all new motors giving the results of the horsepower testing. However, he concluded with the promotion of a “dynamo and use this method of testing, for it has the advantages of being able to test the motor exactly as it will run on the tricycle; I mean without the large fly-wheel which Mr. Sangster uses with his dynamometer, and takes away when he has finished testing.”

1900 - The First engine

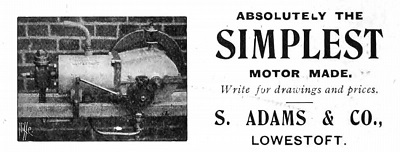

The connection with Aster probably resulted from Walter's development of a 3 h.p. single cylinder water cooled engine that was originally intended for marine use where water cooling was the obvious choice.

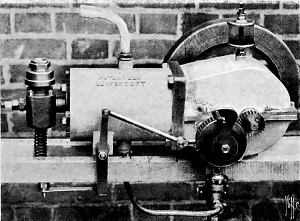

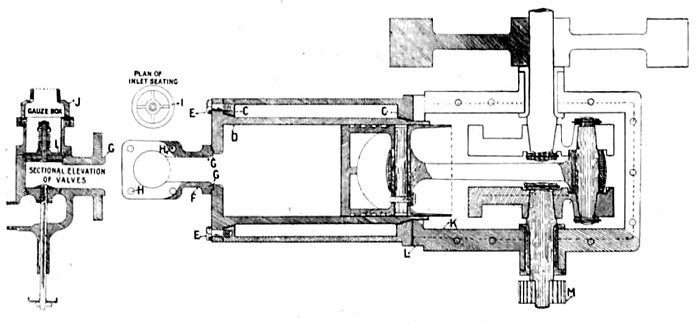

The picture of the engine published[iii] in February 1900 shows a well-made engine with Aster Ltd, Lowestoft cast into the water jacket. The marine origins are evident in the horizontal layout with lugs on the water jacket and the horizontal split crankcase which would allow the upper part to be removed to gain access to the crank assembly without removing the engine from the boat although the exhaust valve mechanism would be vulnerable to flooding of the bilge.

The design incorporates a number of features that would be used in subsequent Adams designs. The De Dion engine initially had the valves at the side of the cylinder although the automatic inlet valve was moved over the exhaust in 1898 but they were both side valves whereas the Adams motor has the valves mounted on top of the cylinder and are bolted on to the flat head.

Walter’s aero engines used a similar arrangement although they were parallel and in line with the cylinder axis. Also notable is that the fixed head cylinder is held in place by the substantial water jacket.

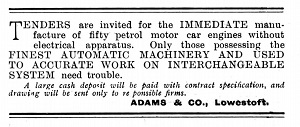

Two weeks after that article appeared Adams placed an advert in The Autocar of 24th February inviting tenders for the production of fifty engines offering a large cash deposit so there must have been a substantial number of orders following the article. At that time, it was standard practice for manufacturers to take orders with a deposit for automotive goods that had not been produced. The following week The Autocar reported that they had received a wholesale catalogue from Adams & Co containing details of four different engines including one that was vertically mounted for cars together with components to make a car including frames, gears axles and pulleys.

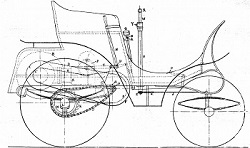

In March the advert below was aimed at readers of English Mechanic wishing to make their own cars using the articles that appeared from January to March 1900. Although the articles included a full description of how to build the engine from scratch this would have been outside the abilities of all but the expert machinist. The design was for a horizontal single cylinder water cooled engine with spark ignition for which the readily available Adams engine was ideally suited.

As a result of the article a large number of letters to the original Adams company in Lowestoft run by the mayor, so Adams was forced to change the name of the company to S. Adams and Co. to avoid confusion although it may indicate that Susan took over the running of the company. From that point on the adverts just showed the engine and was clearly targeted at the do-it-yourself car builder.

The drawing on the right shows the English Mechanic design with the horizontal engine at the back with belt drive to the gearbox with final drive by chains. The adverts for the engines continued until the end of the year until agreement was reached for the sale of manufacturing agency rights to R. O. White and E. M. Davey who formed the New Century Motor Syndicate Ltd. with a capital of £3,000 in January 1901.

The use of syndicate in the company name indicates that the company intended to licence manufacturing rights rather than manufacture and sell vehicles following Harry Lawson’s approach with the British Motor Syndicate. In 1902 Messrs Hoyle Brothers and Co. Ltd of Brighouse announced the New Century voiturette (below) which had a single cylinder water cooled engine mounted at 25° to the horizontal which could be a development of the syndicate’s licence.

The 1901 census shows that Walter and Susie were living in Wood Street, Northampton adjacent to the works of the Dorman Engineering Company who were starting to make motorcycles. Walter now described himself as a motor engineer in the census but the enumerator changed it to motorcycle to reflect Dorman’s products.

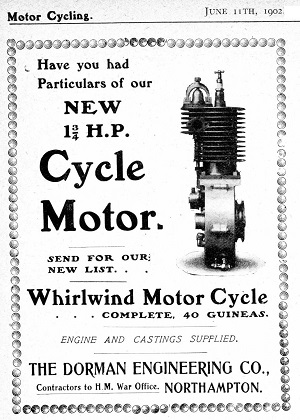

The Motor Car Journal reported on 21st December 1901 that Dorman had announced their new Whirlwind engine primarily intended for launches but adaptable to car, agricultural machinery, saws, pumps etc. The first advert for the new engine was in April but didn’t have a picture of the engine suggesting that it had not been finalised.

The June advert shows an engine with a more conventional side valve following the layout established by Minerva but introduced the single screw fixing for the automatic inlet valve assembly to avoid the more usual thread fixing that would have been prone to corrosion in a marine environment was to become one of the hallmarks of an Adams design.

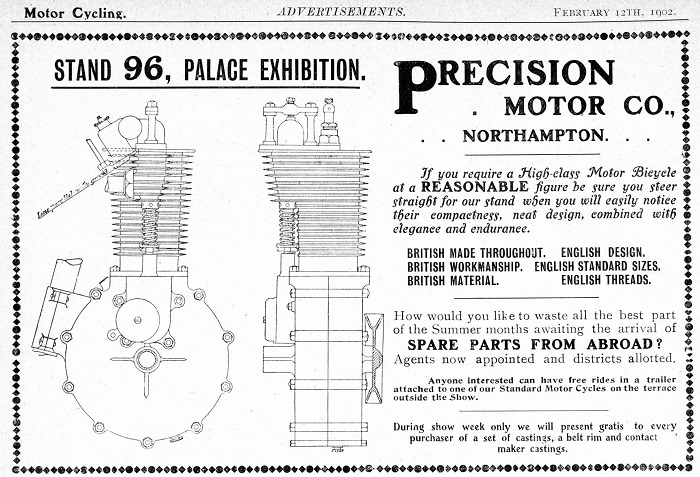

By the December 1902 exhibition, the Whirlwind range had expanded to five engines of sizes up to 3 h.p. that were offered for the 1903 season. The special feature of an easily removable inlet valve and seating follows Adams previous practice which was carried over to his later designs. Another supplier based in Northampton from early 1902 was the Precision Motor Co. whose engine looked suspiciously similar to the Dorman product.

Adams was still in Northampton in June 1902 as he was fined 20s for furious driving above the legal limit which in the town could have been lower than the national 12 m.p.h. By July 1903 he was driving a 16 h.p. Boyer which he raced in Phoenix Park, Dublin’s speed trials where he won his heat in the Touring class for cars costing over £300, beating a 24 h.p. Darracq in his heat. He had clearly come a long way from his failed bicycle business.

Move to the New Forest

By 1905 Adams had moved to the New Forest as in October he was fined £5 for exceeding the speed limit at Wisley. As events regularly started at Ripley, close to Wisley, he was probably competing in an event as he gave his address as Lyburn Park, near Lyndhurst. The fine was hefty so either his speed was well over the limit or the magistrates considered that he could afford it.

As his company appeared in the 1907 Kelly’s Hampshire directory as Walter Adams motor manufacturer based in Redbridge, he could have been preparing to set up there a couple of years earlier. The directory gives Harry James Foot, shopkeeper and insurance agent, as living at The Yews so Adams moved to Redbridge during 1907.

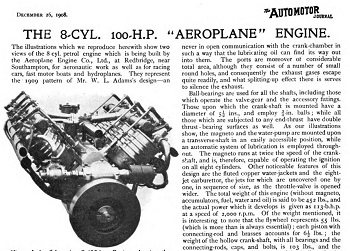

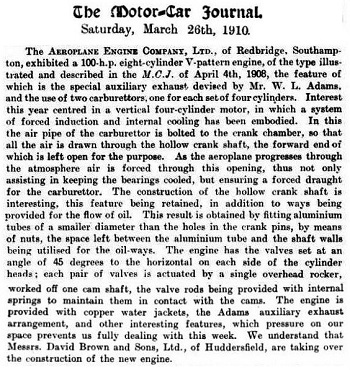

Certainly, he was actively promoting his 60 h.p. 90° V-eight-cylinder racing car engine which had his own version of an auxiliary exhaust with openings in the cylinder uncovered by the piston at bottom dead centre.

He had certainly moved to Redbridge by that time as the patent for his auxiliary exhaust [iv] gave his address as The Yewtrees although the 1908-9 Kelly’s directory entry retained its earlier name of The Yews in addition to the listing under Motor Car Manufacturers. The patent for improvements in carburettors [v] filed a week later gives his address as Redbridge Motor Works, Redbridge. Judging from the newspaper reports which state that he made the V-eight engines in his spare time, his main business up to 1908 was car repair and maintenance.

That changed in 1908 with the Olympics featuring motor boat racing for the first time. This was held on the Solent (Channel between the Isle of Wight and the mainland of southern England).

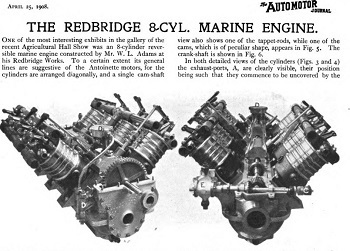

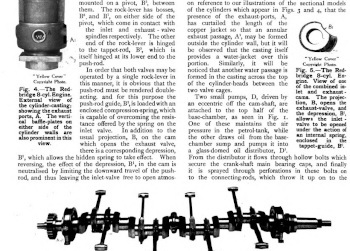

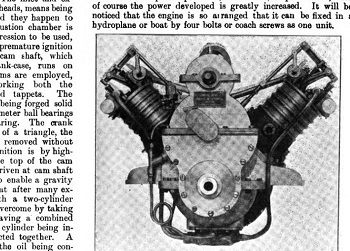

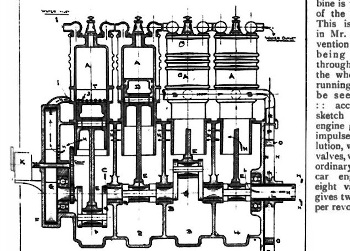

This would have generated a demand for marine racing engines for which the Adams design was readily adapted. The Automotor Journal of 25th April carried a two-page spread on the details of his engine including his patented auxiliary exhaust and carburettor which he expected to produce 100 h.p. The engine incorporated a number of other unusual features like a single rod to operate each pair of valves by push and pull. This required a single cam with a depression for the inlet valve and the more usual projection to operate the exhaust. A spring strong enough to overcome the light spring on the inlet valve was necessary to pull the rod down into the depression on the cam.

Even more unconventionally, the light spring on the inlet was to allow the engine to be run backwards when it would operate an atmospheric valve which a number of manufacturers were still using. This was ideal for marine use as it dispensed with the need for a reversing gear but its use on a car, which was also proposed, was probably not practical as few drivers would wish to go as fast in reverse as forward with a 100 h.p. engine.

The publicity gained by this and other similar articles proved successful as according to the Lloyds List dated 27th August 1908 “Lord Royston intends to build a new class of hydroplanes... and has commissioned W.L. Adams to design a V-twin engine along the same lines as the V-eight.” This is the first time that Adams is recognised as a designer rather than a manufacturer especially as he is likely to only had the facilities to build prototypes as in the case of his very first engine.

The Aeroplane Engine Company

Although the hydroplanes were boats, 1908 was also the year in which the interest in flying came to the fore. Lord Royston was an international balloonist and Adams would have realised that his engines were suitable for aero use as they had high power coupled with low weight.

Adams formed the Aeroplane Engine Company on 22nd September 1908 with capital of £2,224 with a thousand shares held by Adams and Joseph Jaques, gentleman, who presumably provided the £1000 capital required to set up the business.

Other shareholders were

Alfred Chandler (200) the Registrar of births, marriages and deaths in Redbridge.

four shareholders gave the same address of The Firs:

Bassett Allan (20), a clerk in holy orders

Sara Gunn (1)

Arthur Jaques (1)

Susie Adams (1)

Charles Hiscock (1)

Chandler’s shares were unpaid as he had provided the funding for the work on the initial engine and he subsequently entered into an agreement for the rights to Adams patents as security to his investment. The future looked bright as by December there were reports orders for a couple of V-eights in addition to the V-twin for the hydroplane to be raced at Monaco as well as one for a new racing car to race at Brooklands. This is possibly the four-cylinder engine for the Star aeroplane which debuted in 1909 but with a standard car engine.

By December 1908 Adams have converted the marine engine to an aero engine where the reversing mechanism was no longer required and managed to publicise the company with this full-page article.

A report in the Southern Echo dated 15th February 1909 implied that the Aeroplane Engine Company had moved to new premises in Redbridge in a fairly spacious corrugated iron building. The reported hoped that this would be the beginning of a new local industry but more interestingly suggested that with the provision of a landing place at Cowes that Hampshire looked like proving a suitable rendezvous for flying machines. As Cowes is surrounded by hills this would suggest that the harbour would be suitable for flying boats which were confusing also known as hydroplanes when they appeared. By 1909 Adams had moved away from car manufacturing and was no longer listed as such in the Kelly’s directory. He produced the V-twin for the hydroplane which would have provided income for the company if he sold manufacturing rights as well.

This would have allowed him to continue with his work on innovative aero-engines and he announced an ambitious four-cylinder two stroke design. The N.E.C. was an established four-cylinder aero engine that was available by this time and powered the Noel Pemberton-Billings PB1 aeroplane which he unsuccessfully attempted to fly at nearby Woolston in 1908/9 which may have inspired this approach. Very few further details emerged although Adams did attempt to use the exhaust gases to drive a turbine attached to the crankshaft. His much later reference to internal combustion turbines not being available may reflect the problems he would have faced in keeping the vanes in one piece at high temperatures. The reporter may have been confused, he did get the middle initial wrong, as a 45° firing angle would have required a 90° V-eight rather than a four.

Perhaps it was the success of the smaller V-twin engine together with the granting of the two patents in May that allowed Adams to refinance the company. The company return and subsequent annual report showed that on 1st October the Jaques and Gunn had transferred their shares to Adams who then held 2023 and the Chandler shares transferred to four local shop keepers: Shalders (100), Saunders (25), Smith (25) and Bailey (50). However, apart from a mention in the Motor Car Journal of 30th October 1909 that they had seen the drawings of the new four-cylinder two stroke engine fitted with a turbine nothing more was seen until it was displayed at the Bournemouth Air Show. The Kelly’s directory for 1910 no longer showed Adams in Redbridge and the Redbridge Motor Works was taken over by Pope & Co of Christchurch.

Although of no apparent significance to Adams, The Motor car Journal of 18th December 1909 announced the discovery of a new aeroplane being constructed by the Star Engineering Company of Wolverhampton with the motive power supplied by a Star 15 h.p. engine. However, this was to the start of the All British Engine Company story. By 19th February 1910 the same journal reported that the Star aeroplane would initially use the same racing engine that was used in car at Brooklands but a more powerful but lighter aero engine of 40-50 h.p. would be used in the future and Star would make a standard production item.

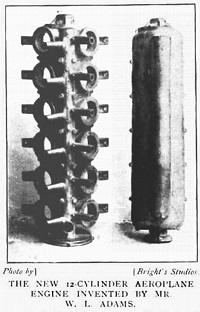

At the Olympia Show in March 1910 the Aeroplane Engine Company exhibited their V-eight engine but now for dirigibles as well as a four-cylinder aero engine using the usual Adams patented features including crankshaft, forced induction and forced water and oil circulation and a carburettor designed to work at any angle. The detachable valve boxes held down by a cross yoke and the hollow crankshaft are typical Adams features. Star exhibited their aeroplane together with its aeroengine and a second engine. It is therefore not surprising that the four cylinder aero engine on the Aeroplane Engine Company’s stand had a remarkably similar specification although there is more detail about how it worked including the forced induction which was simply the forward facing duct to the hollow crankshaft which both cooled the crankshaft and increased the pressure albeit at the cost of an extended inlet path. Once again Adams acted as pre-production designer as they also announced that production of the engine would be carried out by David Brown and Sons of Huddersfield.

The 1910 International Air Show

The International Air Show at Bournemouth, in the week starting Sunday 10th July 1910, provided a significant opportunity for Adams to display his engines and he took a stand to do this. Not only did he have the V-eight engine but he also had the four cylinder two-stroke as a complete engine on display. Before the show the Bournemouth Graphic had an exclusive article on this radical departure from the usual Otto cycle engines.

The New Engine Company (N.E.C) already had a four-cylinder two stroke engine in production which used a Rootes blower to force air into the cylinders. Adams seems to have used the Clerk cycle approach with pressure fed into the crankcase and traversing a series of tubes to reach the carburettor which was meant to be positioned at the end of the crankshaft. Quite how the air reaches the inlet ports on each cylinder is unclear and as neither the picture nor the drawings show a carburettor.

The most intriguing claim echoes the earlier one that firing occurred every 45° of crankshaft rotation. This time it states that it will be seen by the accompanying sketch that the engine gives eight impulses per revolution without any valves whereas the ordinary 4-cylinder engine with eight valves only gives two impulses per revolution.

Whether or not the two-stroke engine would ever fly, the Show proved to be a turning point in the future of the Adams engines as he met Ronald Charteris who was responsible for arranging accommodation and garaging for the more affluent spectators.

The outcome was the registration of the W. L. Aero Engine Company on 8th August 1910 with Walter Lawson Adams, Motor Engineer of The Nest, Surrey Road, Bournemouth and Ronald L. Charteris, gentleman of Stanpit Grange, Christchurch, each initially having a single share. Two weeks later the register of directors was filed with two gentlemen from Bournemouth and Ernest Noel of Belgravia who was related to Charteris and provided the capital for the company.

The capital was increased to £2,250 in September with all shares paid in cash: Adams 750, Charteris 500 and Noel 500. Matthew Haygarth, solicitor and company secretary took 35 shares and the registered address for the company was at his chambers.

In view of the similarity of the designs of the initial engines exhibited at the show by the A.B.C. company in 1911, there must have been an agreement to sell the rights to the company which may have been the source of the £750 that Adams contributed. Having sold his designs, Adams would go on to new designs and lost interest in the company selling his shares on 7th January 1911 to Albert Francis whose holding went up to 925 out of a total of 2625. Both Ernest Noel and Charteris held 625 so they would have needed the Francis vote on 31st January 1911 to pass a resolution to change its name to the All British (Engine) Company which became ABC.

Consulting Engineer & Technical Expert

Adams moved to Bournemouth and continued his work on novel aero engines and the Bournemouth Graphic announced 10th March 1911 his latest creation, a new V-8 and V-12. In April he advertised as WL. Adams, Consulting Engineer, 46. Surrey Road, that he had a vacancy for a well-educated YOUTH as pupil to learn throughout the manufacture of Aeroplane Engines.

He had joined with Major Sweetzer, a motor dealer, who had taken over the Imperial Motor Works in Holdenhurst Road, Bournemouth and installed extensive plant for building aero engines as well as cars. The article also confirmed that it was the Adams engine that was at Brooklands despite ABC making that claim.

The real business of the Imperial Motor Works can be judged from the inclusion of the name of the patrons of the establishment with the notable 120 h.p. Itala owned by Mrs Thornton that makes Ethel Locke King’s 24 h.p. Itala a mere toy.

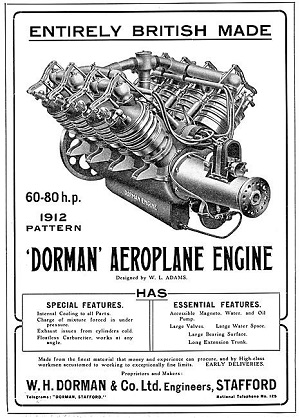

In July Adams was reported to have obtained spacious workshops in Gordon Road, Branksome which he had equipped to machinery to allow him to produce his engines. His role at Imperial was therefore more as an engineering consultant that as a designer for their aero engines. As Sweetzer became a director of the Aeroplane Engine Company in September it would appear that the car side had been separated from the aero engine side. This coincided with the launch of the new V-8 although there was no mention of the accompanying V-12. The engine had all of the usual Adams features including a push-pull rod to actuate the valves but they were now inclined which would allow them to be larger than when parallel.

Although the engine was entered in the Alexander Engine Competition it did not appear. The most interesting comment in this article is that these engines were made at the Redbridge Motor Works rather than the Imperial Works in Bournemouth. This means that the Aeroplane Engine and the All British Engine companies shared the same premises and explains why the latter took their engines to Brooklands by road and why they looked the same. The most likely explanation is that in 1911 Aeroplane Engine made the engines using the Adams patents and ABC sold them. ABC moved to Brooklands where they also had a workshop in addition to a hanger so they would have been able to diverge from dependence on Adams and replace him with Granville Bradshaw.

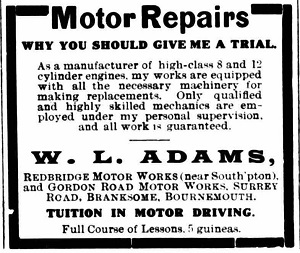

In October Adams started advertising that his mechanics from the Aeroplane Engine Works were highly skilled and qualified to undertake car maintenance. From November 1911 until the end of the year Adams advertised for car maintenance without mentioning aero engines and even offered to teach people to drive. It is notable that he continued to run both the Redbridge and Gordon Road works. Confusingly Pope & Co of Christchurch had taken over the Redbridge Motor Works in name only from June 1910 which they used in their adverts which probably means that they took over part of the Redbridge Works until the middle of 1911.

These changes were brought about by the sale of the rights to his latest V-8 design to W. H. Dorman and Co. of Stafford. These were launched in late 1911 and were in production by August and this cutting shows it was one of the few examples of Adams designed engines that actually flew. Even so, by December The Aeroplane was implying that significant changes to the design were required.

As this was to be the last of his designs, this meant Adams no longer has any need for significant manufacturing machinery as by this time ABC had established themselves at Brooklands and no longer needed the earlier Adams engines.

By the start of 1912 Major Sweetzer was no longer interested in aero engines and press reports indicated that he was solely interested in car maintenance and storage. The directors of the Aeroplane Engine Company agreed to voluntarily wind up the company on 24th June 1912.

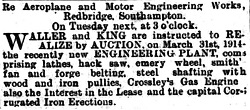

The liquidator’s analysis of balance dated 11th June 1914 showed that there had been a problem with the agreed sale of the works in September 1912 for £170; the sale had not been completed so a court order was required to enforce performance of the contract so it was not until 31st March 1914 that the Aeroplane Motor Works, Redbridge, Southampton was sold at auction.

At the end of April 1919 there was a large fire “at the Redbridge Motor Works in the early hours of Wednesday practically whole the building and its contents were destroyed. Loss includes motor-lorry, drilling machine etc.”

This was undoubtedly a difficult time for Adams as his wife claimed in her 1915 divorce petition that he had deserted her three years earlier and was living with Ada Plater in Tooting which was their then current address in Kelly’s Directory. The list of addresses given in the petition give a further insight into their lives as they lived in Theobalds Road, Holborn when they left Lowestoft before moving to Northampton. In 1900 Holborn was the centre of the motor trade and it was at this time that they sold the rights to the first engine to the New Century Syndicate.

More surprising is the lack of any other addresses after Northampton to her current address of 5, Limes Road, Weybridge. This could explain why Walter was fined for a motoring offence in Ripley if they bought the house in Weybridge and Susie continued to live there. Certainly, Kelly’s Directory doesn’t list her in Redbridge which leaves the 1911 census when she claimed to be staying at the Nest in Bournemouth. It is possible that she visited Walter at the time of the census but the form does have an unusual feature: usually the form returned is completed by the head of the household but in this case, it was clearly filled in by each of the four residents which could indicate they may not have been present at the time.

Adams joined up as a Royal Navy reservist when the war started in 1914 and was promoted to temporary Lieutenant in the Royal Naval Air Service on 3rd July 1915 and remained on the reserve list until 1918. His patent [vi] on improvements in mounting cylinders dated 2nd January 1918 shows that he worked in the Air Department of the Admiralty at Victor House, London although his application [vii] on flexible couplings dated 2nd September 1917 gives his address as Thorpe Lea Road, Peterborough so he was never in the same place for very long. In 1918 he was on the electoral role of Frien Barnet where he lived at Keswick, Athenaeum Road with Ada Adams so this raises the question as to whether the divorce from Susie was to allow him to marry Ada although there is no record of his second marriage.

He had formed a partnership with Herbert Robert Wade as the Laxtonia Engineering Company based in Peterborough that was to produce a V-12 engine for cars but this was dissolved on 25th March 1919. His next two British patents were filed in 1924/5 while he was living in New Haven, Connecticut and were for improvements in buffers [viii] for automobiles and suspensions [ix] for automobiles.

He retained links with Britain as he is listed in the London Post Office commercial directory of 1925 as Adams Walter L., 9, Friday Street E.C.4. He was back in England with Ada for 1928 electoral roll living at 14, Alexandra Grove, Finchley where he was permanently banned from driving and fined £30 with £10 10s costs.

His last patent for improvements in pivots [x] was filed in 1931 when he was living in Gamlingay, Cambridgeshire. This would explain why he was up before the magistrates in October 1930 for driving without a licence when he unsuccessfully applied to the Highgate magistrates to lift the suspension.

Roger Bird

External Links

[i] British Patent GB189729230 Joints for Cycles, Motorcycles and Machinery

[ii] British Patent GB189812443A Improvements in Football Bladders

[iii] The Autocar 10 February 1900 page 134

[iv] British Patent GB190727877 Improvements in cylinders for internal combustion engines

[v] British Patent GB190728432 Improvements in Carburettors for explosion engines

[vi] British Patent GB112462 Improved means for Mounting Cylinders in Internal Combustions Engines

[vii] British Patent GB112402 Improvements in flexible couplings.

[viii] British Patent GB258292 Improvements in buffers for automobiles

[ix] British Patent GB236243A Improvements in suspensions for automobiles

[x] British Patent GB396377 Improvements in Pivots