This car, which is of a high standard of design, employs a horizontally opposed air-cooled engine, designed by a well-known aircraft engine designer. The car itself is of original and sound design throughout, and has established a very good reputation for reliability, durability, and performance.

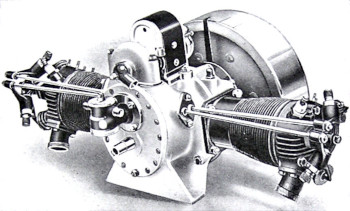

The engine, which is shown in outside view in Fig. 148, is of the horizontally opposed two-cylinder type of 91.5 mm. bore and stroke giving a capacity of 1,203cc, and an R.A.C. rating of 10.37hp, although the maximum bhp developed on the testbed has exceeded 30.

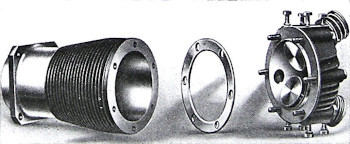

The cylinders, a dismantled view of one of which is shown in Fig. 149, are of steel, machined from the bar; they are finally ground after machining to within limits of plus and minus .00075in.

The cylinder heads, which are detachable, are of cast iron, with a large amount of cooling area. An insulator is placed between the head and barrel to assist in equalising the temperatures at the front and rear ends of the cylinder, in order to prevent distortion. Overhead valves of high tensile steel are fitted in the cast-iron heads; the valves are of large diameter, giving ample port area, and are provided with short and stiff shanks. Short nickel-chrome steel helical springs are fitted, two to each valve. The rocker arm bearings are provided with screw-down lubricators and means for readily adjusting the clearances are fitted.

The crankshaft is machined from the solid out of a one-piece steel stamping and is very strong and rigid.

It is mounted on Hoffmann radial ball bearings, disposed in an overall dimension of only 9¼in; a ball-thrust bearing is also fitted to take the declutching end loads.

The connecting rods are provided with roller (assembled bearings into position), at the big ends and phosphor-bronze ones for the small ends.

Cast-iron pistons of very light construction, with three rings above the alloy steel gaugeon pins, are employed; a scraper groove, with holes running into the inside of the piston, is arranged just below the lower ring.

Lubrication is effected by a special type of mechanical pump of the rotary plunger type, driven through a worm-reduction gear; no valves are employed. Oil is delivered direct to No. 1 cylinder and also to the crank case sump, whence it passes by splash to the big end and main bearings and also to No. 2 cylinder. An adjustable sight feed is provided on the instrument board.

Carburation is by venturi-type Zenith placed carburettor, centrally behind and above the engine.

Ignition is by magneto, conveniently situated, and with variable timing.

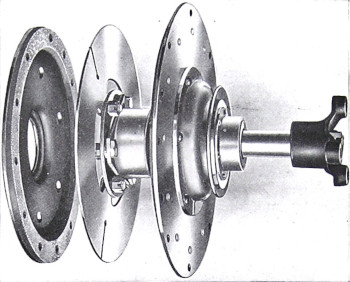

The single plate, steel and Ferodo clutch employed is shown in Fig. 150. The Ferodo-lined discs operate on either side of the single steel-driven plate, the former being driven directly from the flywheel shaft.

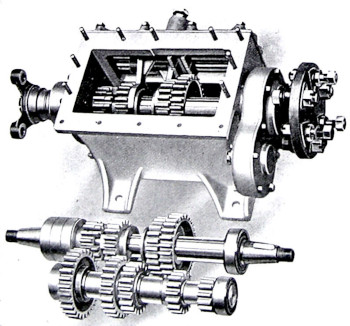

A four-speed gear box is employed, of the central change type; the gear ratios are 4.5, 6.5, 9.45 and 13.77 forwards and 18.36 reverse. The gears run on heavy-duty ball and roller bearings.

A steel disc universal joint is interposed between the driven steel disc and the sleeve to which its motion is transmitted, the sleeve being mounted on the clutch shaft.

There is a Hardy flexible disc type universal joint at both the front and back of the gear box. A speedometer drive is arranged at the rear end of the gear box.

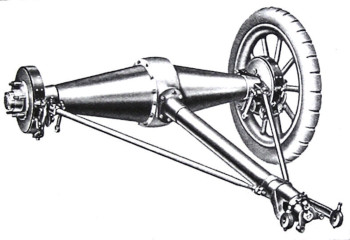

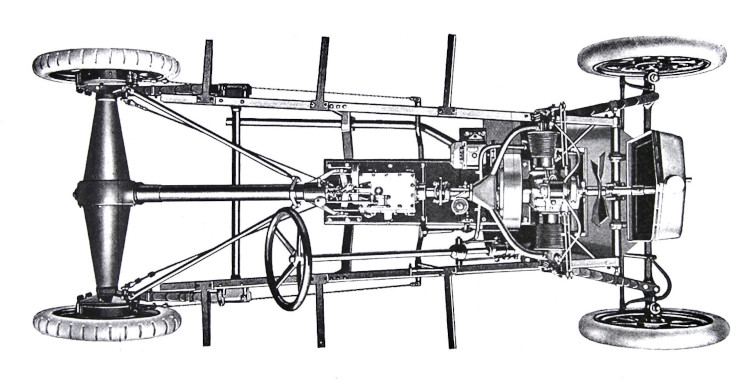

Transmission is by enclosed propeller shaft, in the torque tube, which is forked. The forked ends are free to rock in bearings anchored to the frame crossmember, and additional triangular tie-rods are run from the forked member to either side of the back-axle casings.

The back axle is an interesting piece of design. Spiral-bevel final drive and bevel pinion differential are employed, the driving shafts being tapered at their outer ends to receive the road wheel hubs.

The axle casing is formed of two heavy gauge rolled steel cones, riveted to pressed steel discs at their inner ends, which discs carry the main bearings. These two steel cones taper from the wheels up to the outside diameter of the aluminium casing in the centre, and thus provide a very strong and rigid construction. The central portion, containing the spiral bevels and differential gear, is provided with baffles to prevent the oil from entering the taper tubes and thereby flooding the hubs. Separate oilers are provided for the hub ball bearings.

The foot brake is of the external contracting type, and the hand brake of the internal expanding type; both operate on the rear wheel drums.

Steering is on the nut and worm principle, with adjustment for wear. The nut and worm are of square thread section, with large surfaces, and the thrust race fitted is adjustable for end wear. Spring-loaded ball-and-socket joints are fitted to all steering arms.

Springing is by outwardly splayed quarter elliptics at the front, and also by semi-elliptics at the rear.

As this engine is air-cooled, the radiator fitted is simply a dummy, but it allows the cooling air to pass through, and gives a pleasing appearance to the front of the. car. It also supports the front end of the petrol tank, which holds six gallons of fuel, and the radiator cap is the petrol tank filling cap. The oil tank is also formed integrally with the petrol tank and holds one gallon of oil.

The frame is of pressed steel channel section, of straight form, but splayed outwards, in plan, towards the rear. It is well braced laterally with cross-members.

The wheelbase and track are 8ft 6in and 3ft 11in respectively, and the overall length and width are 12ft and 5ft respectively.

The ground clearance is 8½in

The chassis weight is about 8½cwt.

It will thus be evident that, with the relatively high-powered engine fitted, and the low body weight, a high power-weight ratio is obtained. This fact is reflected in the excellent performance of this car, a top speed of 50 to 55mph being easily possible.

The chassis is fitted alternatively with two- or four-seater bodies, and the fittings and equipment include a polished aluminium bonnet, two doors to front seats, side-curtains, lighting and ignition switches, oil-indicator, speedometer, voltmeter, dimmer, dashboard shelf, etc.

The petrol consumption of this car averages about 40mpg.

From “Modern Motor Cars Vol.3” - written by Arthur W.Judge and published by Caxton Publishing Company Ltd in 1924 – Courtesy of Axel Höh