Note from webmaster: any reference in this article to ABC meaning All British Cycle is incorrect but the rest of the article contains valuable information. ABC stands for All British (Engine) Company

When Granville Bradshaw handed over the drawings for the new ABC motor cycle to the Sopwith Aircraft Company in 1919, it was generally believed that he had designed its remarkable unit-construction horizontally opposed twin-cylinder engine unit in less than three weeks. That was the belief of T. O. M. Sopwith of the Sopwith Aircraft Company. Bradshaw made a promise to Sopwith that the new design would be ready in that time, and Sopwith made what may have at the time seemed a safe and profitable bet with Bradshaw to the effect that, for each day's delay after the stipulated three-week period, Bradshaw should pay him E 100 while he would pay Bradshaw, in the event of the design being ready inside that period, a similar sum for every day saved. It turned out to be a profitable bet only for Bradshaw, who was ready with ten days to spare and who collected £1000.

However, there are grounds for believing that the design for this new machine was already on the drawing board as early as 1914 when Bradshaw was designing machines for the All British (Engine) Company, the initials of ABC then standing for 'All British Cycle'. Although Bradshaw spent the war extending the application of air cooling from engines of 8hp up to aero engines of 200 or 300hp, he had all probability spent all his spare time quietly working on this new design and one wonders whether Sopwith knew that Bradshaw had metaphorically started the race before the flag dropped. No doubt Sopwith would not have minded in any event, as the new design, the 'Firefly' Lightweight, was in his opinion a winner. The concept of the original Firefly underwent considerable modification before being accepted as the type for production, the variable gear being replaced by a four-speed mechanism, which was a major feature.

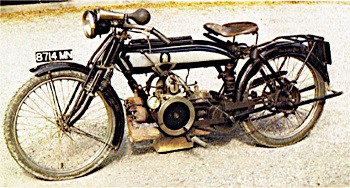

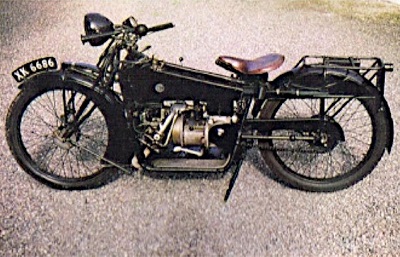

Bradshaw, the ABC Company and Sopwith were drawn together by the events of World War I. Before hostilities broke out, Bradshaw had already designed a fore-and-aft 3½hp twin-cylinder engine with a three-speed gearbox and chain drive. This was used in a machine which was remarkable also for the early use of a spring frame; it sold for €63. At that time, the Company was prepared to accept a 500cc engine for motor cycles, but later the policy changed under the belief that this engine size was too powerful for a solo motor cycle, so Bradshaw turned his attention to designing a 250cc flat twin, which developed over 4bhp.

The first ABC was a 500cc model, the engine being placed fore and aft in the frame and having side inlet and overhead exhaust valves. During the war, the demand upon Bradshaw-designed engines was not to propel cycles, but to pump out trenches at the front lines, the 500cc twin-cylinder unit being considered ideal for the job. For Bradshaw, the utilisation of his engines for this purpose could be considered either a compliment or an insult! With the return of peace, Bradshaw was once again able to pursue his original aims, developing and improving the motor-cycle engine; 'Tom' Sopwith gave Bradshaw that opportunity.

With aircraft production so much in demand during the war, particularly during its latter stages, Sopwith was left in the early post-war days, with a surplus of staff engineers and machinery, but no demand for aircraft. Motor-cycle production seemed a sensible means of utilising the force, and with equipment at his disposal together with a good knowledge of Bradshaw's capabilities, Sopwith's choice of ABC and Bradshaw was an obvious one. The original ABC works were altered to become a laboratory for invention, experimentation and testing of new engineering techniques, while the Sopwith factory provided the staff and facilities for the machines' production.

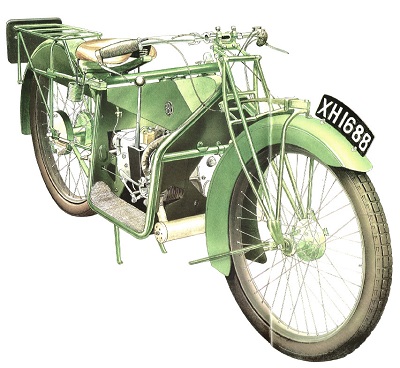

Sopwith's confidence in Bradshaw proved well founded when the new design was put before him for production. It had one-piece steel cylinders with wafer fins, symmetrically designed to avoid overheating, pistons made of aluminium, deeply recessed at the waist, and overhead inlet and exhaust valves; its capacity was 398cc, and four speeds were incorporated in the unit with gate change.

Not content with designing the engine unit alone, Bradshaw also produced the drawings for the excellent cradle frame in which the unit was housed, with front and rear 'leaf-type' springs. Spring frames were not immediately accepted by the motor-cycling fraternity and indeed were not in universal use (or another twenty years. At this time there had been many half hearted attempts to 'spring' part of the frame on several machines. The new Bradshaw forks proved far superior to the many proprietary makes on the market, while internal expanding brakes. both front and rear, ensured greater safety and consistency as the various 'belt-rim' braking systems proved inefficient in wet weather.

No doubt the engine size of 398cc was decided upon to keep down the weight of the machine and it was boasted that the complete machine could be lifted by one man, although it was never emphasised that 'the one man' needed to be built like Tarzan. The Machine was turned out with footboards and leg shields and painted black or grey. No kick starter was fitted at first, so the rider 'paddled' the machine into life. However, when exhibited at the Motor Cycle Show in 1919. it caused a sensation.

The change-over from aircraft to motor-cycle manufacture was a major operation and in consequence the Sopwith plant encountered innumerable problems, which resulted in considerable production delays and but a few machines actually leaving the factory. The original estimate was that five to ten thousand machines would be made each year, but in total only about 3200 were ever produced. Of the few that did manage to 'escape', the reports were all favourable and encouraged further efforts to overcome the snags and increase production.

J. L. E. Emerson performed well on the new ABC in competitions, particularly at Brooklands where he took the one-hour record twice in 1920, averaging 67.93mph on the first occasion and 70.44mph on the second. This meant the little machine exceeded 80mph on occasions (quite a feat at this time) which proved to be another strong selling feature, demand outweighing production. Inflation was a big problem in post-war Britain and with the increase in production costs there came the inevitable increase in purchase price. Originally planned at £70. the machine was marketed in 1920 for as much as £150.

As has proved the case after two world wars, the post-war depression created an admirable market for the sale of motor cycles. The demobilised forces may have had some savings and possibly received some small demobilisation gratuity available to spend on the purchase of transport. However, at the same time, these men would have been obliged to keep an eye on economy in price and running costs and the uncertain job situation which has tended to rule out car purchase and resulted in a gigantic boost to motorcycle sales.

Unfortunately for ABC, their production problems and price increases effectively cancelled out their newly acquired reputation, and orders were cancelled in favour of cheaper, and readily available machines. It has to be remembered that £150 represented nearly twice the annual income of the average working man and that other manufacturers were putting out a model for about £60. Just over three-thousand machines had been turned out by 1921 when the Sopwith factory ceased production.

In the meantime, Bradshaw had not remained idle for he designed a small 123cc single-gear scooter, which was manufactured by the Campion Engineering Company. This Company managed to produce the little machine, with its fairly limited performance, in large numbers (for that period). The method adopted for doing this was to have lines of benches with six components set out on each one, and the engineer at each bench would contribute his part to the construction before passing the growing machine down the line to his next colleague. A regular system for testing the machines was adopted, but this thorough method was somewhat impracticable by present day standards.

Each new machine was ridden from the factory door to Brighton and back, a distance which it may be thought would inevitably have caused overheating with the engine mounted behind the rider, but we are informed by one tester that this was not so. Its- engine was a single-cylinder unit with a turned-from-solid barrel (in common with aircraft practice) and overhead exhaust valve and side inlet, but later models were made with both valves overhead. Since the engine lay on its side, with the fuel and oil tanks above, the direct drive was taken by chain to the back wheel. A model for commercial use was available with a seat (instead of a saddle) on top of a box intended for delivery purposes, although in view of its size it is hard to imagine how delivery of anything larger than a box of cigars could have been undertaken. As scooters were as popular after World War I, there were many makes in production, but probably Skootamota enjoyed the largest sales.

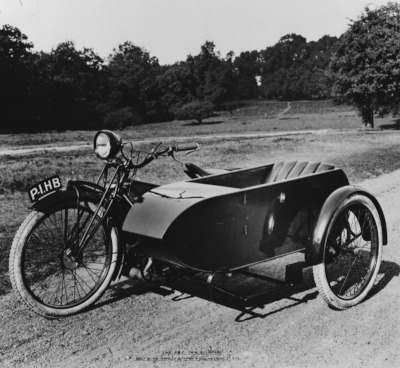

During its life span, the ABC Company did not have any faith in sidecar outfits, but preferred to manufacture a cyclecar. It was made quite clear that their new Firefly should not be fitted with a sidecar, but the production machine, although only 398cc, could be so fitted if desired.

The production of ABC motor cycles in Britain ceased by 1923, although the Gnome Rhone factory in France, better known for its production of ABC aeroplane and car engines, continued to manufacture a modified version of the ABC motor cycle until 1925. The chief modification by the French Company was to increase the engine size, and both 3½ and 5hp models were turned out. These had four-speed gear boxes, and mechanical oil pumps, and cost £100 and £110, respectively.

A sidecar could be supplied and fitted, as the larger engine size meant a far better performance and, consequently, larger sales around the world.

The main problems facing the manufacturers of ABC were in the rocker gear and lubrication. The rocker gear had plain bearings on the English version, which resulted in rapid wear. Alternatives with roller bearings were offered by proprietary manufacturers which served satisfactorily. The lubrication problem was mainly due to the abandonment of the oil pump designed by Bradshaw, but the Sopwith factory used crankcase vacuum in the interests of economy which, in the hands of inexperienced riders, proved unsatisfactory.

Reading the instruction book of the ABC provides a few interesting 'Don'ts':

- don't control the machine with the exhaust lifter - use the throttle and save petrol - and exhaust valves;

- don't pour petrol into the tank except through a filter - the hole in the carburettor jet is much smaller than some of the odds and ends that find their way into a petrol tin;

- don't overdo it when priming the cylinders with petrol, because petrol is a poor lubricant - leave a little room for the necessary air, otherwise the mixture won't fire;

- don't smother the man behind with blue smoke - not he, nor you, nor the engine benefits - only the oil manufacturer;

- don't reamer out the jet - it is the right size and won't shrink.

The instruction book, did, however, contain much useful information to assist the new owner to maintain his machine in good running order, with drawings which could assist the more technically minded.

The BMW is now one of the foremost designs on the road today, with a basic similarity to the ABC. One is left wondering what might have been, had Bradshaw had the chance to develop his design. If the factory had got production going, thus bringing in money to encourage development, if the numerous snags had been overcome more promptly.

From “On Two Wheels Vol.1 Part 1” - written by Eric Thompson