That the A.B.C. should be no longer made is perhaps the greatest tragedy of the motorcycle world.

There are, however, a large number of owners of these peerless machines to whom a few hints might prove of interest. In the first place these little mounts with the big heart are so satisfactory that the best advice one can give to users employing the A.B.C. for ordinary purposes is to leave well alone, and merely confine themselves to carrying out the simple instructions contained in the instruction book!

The A.B.C. is not, as some affirm, a short-lived machine, and, with reasonable care and intelligent handling, it will prove as reliable and satisfactory as any other first-class make.

As the A.B.C., with its high speed motor, four speed gate, change, and indestructible clutch, is peculiarly adapted to the requirements of the sporting rider who likes competing in hill-climbs and speed events, the writer offers a few hints which will enable a keen rider, to get the best results out of his mount.

It 'must be presumed that the reader is generally familiar with internal-combustion principles and practice, as any attempts to enhance efficiency would be clearly inappropriate by persons of no knowledge of what they were doing.

Keep to the Standard Camshaft.

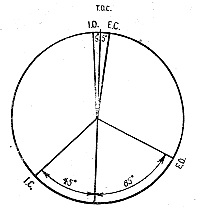

In the first place, unless it is proposed to go in for really serious speed (by that the writer means speeds in: excess of 70 m.p.h.), the use of other than the standard camshaft is not advisable. To alter the existing cam profiles is work which should only be undertaken by the most experienced supermen among tuners, while to have a special camshaft made is not only a job for absolute experts but is frightfully expensive. The best average timing for getting the utmost possible speed without altering the standard camshaft and without impairing the nice all-round running of the A.B.C. engine is:

Inlet opens 5 degrees early.

Inlet closes 45 degrees late.

Exhaust opens 65 degrees early.

Exhaust closes 5 degrees late.

Now, by far the most important thing to increase the "revving ' properties of the motor is to synchronize the valve timing on both cylinders. The only way to time a multi-cylinder engine when the best results are desired is to time each cylinder off the flywheel.

If a reader takes the trouble to do this, he will probably get a shock on verifying the timing of each cylinder by finding a discrepancy of as much as 15 degrees or 16 degrees between the timing of corresponding valves. For instance, he may find that one inlet opens 12 degrees earlier than the other valve, or perhaps one exhaust may close 11 degrees later than the exhaust valve in the other cylinder.

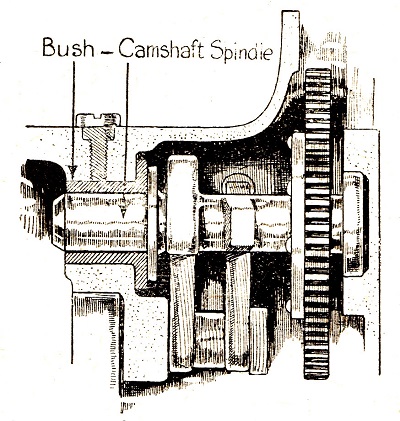

At first sight it may not seem clear how this can occur when a single cam (inlet or exhaust) lifts the corresponding valve (inlet or exhaust) in both cylinders. It may be caused by the in equality of the faces on the rockers interposed between the cams and the push rods, or by slight errors in machining (which, remember, are cumulative), or a combination of both. The remedy is to locate the fault and replace the bushings if therein lies the trouble, or to alter the contour of the rocker heel where it bears on the cam (the rocker is dead hard and can only be ground, care being taken to remove only an infinitesimal amount between each " offering up " of the parts) .

By this means, in conjunction with the adjustment provided at the 'outer end of the valve push rods, it will be possible for a patient and careful rider to get the timing of each cylinder accurate to within 5 degrees of the other.

On the Question of Clearances.

View showing plain bearing at rear end of camshaft. It is essential that this be a good fit in its bush, but at the same time run without friction.

Remember that for speed, the actual clearance between the overhead rocker and the valve stem (within reason) does not matter. It is far more important that the valves function at the same points in the different cylinders; therefore, provided the lift is not seriously interfered with, the adjustable tappets should (for speed) be used to secure uniform opening, closing, and dwell in both cylinders, or, rather, for the fine corrections to the valve operation after as much as possible has been done by attention to the cam rockers and bearings as described above.

It is assumed, of course, that the engine has already been rebalanced. This again is work that should not be attempted by un unskilled tyro, but may be entrusted to a good engineer accustomed to balancing high-speed internal combustion engines.

Much may be accomplished by polishing such moving parts as are not mounted on ball or roller bearings; for instance, the back bearing of the camshaft, gudgeon pin or bush. In fact, all plain bearings should be worked up with metal polish until they are absolutely free from the slightest friction. This is a wearisome job, but if done well it will give an appreciable increase in the revs.

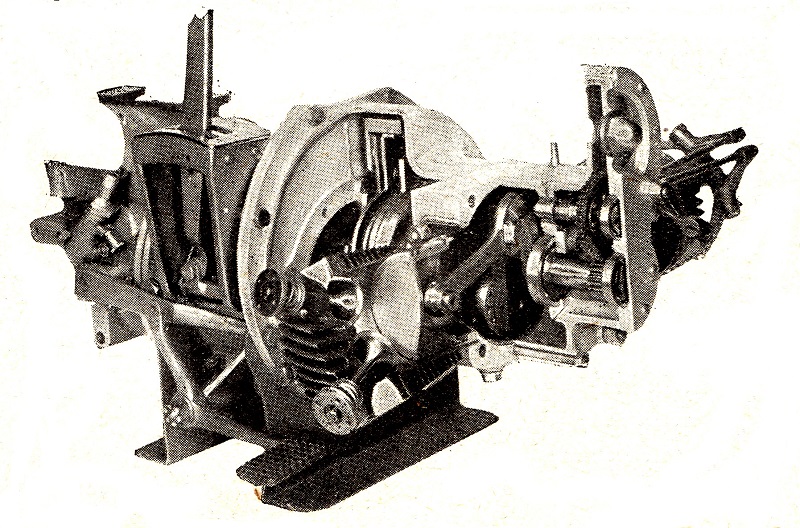

Section showing internal construction of the A.B.C. engine. Note pronounced spherical conformation of combustion space

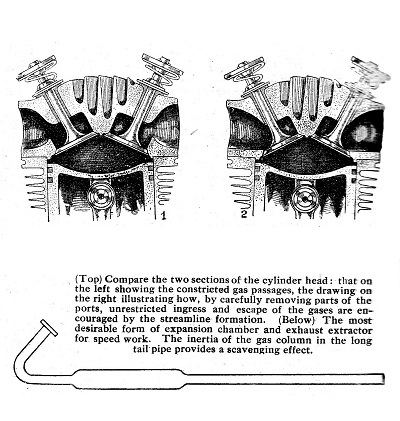

Streamline the Ports.

The next thing to attend to is the streamlining of the inlet and exhaust pockets and ports. This job will easily take a week or ten days if done, say, in the rider's spare lime in the evening, but the results make 'the drudgery worthwhile.

The valves should be carefully ground in, and finished off by working in with metal polish.

Do not alter the shape of the valves, and on no account employ other than A.B.C. valves. Stronger springs than standard will, however, be necessary. Send a new A.B.C. spring to Terrys with a request that a set of similar but, much stronger springs be supplied.

If worn, fit new inlet valve guides, but, unless badly worn, the old exhaust valve guides should be a nice "sloppy” fit, and, in consequence, suitable for speed work. Examine the carburetter and induction manifold. These should be dead smooth; if not, make them so. The carburetter, when in the wide open position, should present a full, clear view right through the throttle barrel.

Watch Your Throttle.

Make quite sure when the lever on the handlebar is set to wide open that the full-bore throttle barrel is in the position. If not, rectify by the adjustment on the Bowden wire stop.

For speed work two long pipes will be found to give better results than the standard arrangement of silencer and central tail pipe. These pipes are preferably built up in three sections, the inlet and outlet, being welded to the larger diameter expansion chamber. The internal diameter of the pipes should be the same as that of the orifice of the exhaust port. Care must be taken to see that no projections mar the internal streamlining of the extractor assembly. Keep the bend as gradual as possible.

Note that, as the cylinders are appreciably staggered, one pipe must be correspondingly longer than the other.

When fitting packing joints to the exhaust flange make certain that the hole in the washer is the full bore of the port. Before entering an event, remove and empty the tank, washing out both compartments with petrol. Refill with oil, which ' must be passed through gauze, and petrol strained through a chamois leather.

Nothing is more galling than to have all one's careful preparations set at naught, by a piece of dirt in the fuel supply.

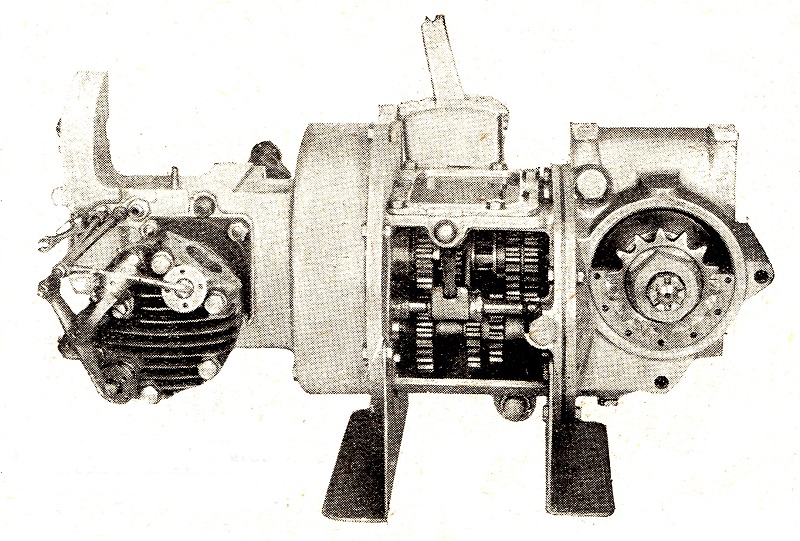

Near-side view of "en-bloc" motor-transmission group. Gearbox with side cutaway to show gear-set assembly.

Which Jet to Use.

The best jet to use is No. 70, but as jets bearing the same number vary slightly in length and discharge, try half a dozen No. 70 jets, adopting the one that gives the best results. Scrap the anti-blow-back cowl on the air intake, and fit, a trumpet-shaped extension about 4 ins. long. Be careful to ascertain that the internal surface of the joint between this and the carburetter is dead smooth and presents no alteration in diameter.

Use the standard magneto timing for hill-climbs, but for pure speed work on the level one tooth advance will give another mile or so an hour. Set the points to open very slightly, and fit two springs to the contact breaker.

For the actual event “K.L.G." plugs, type F 12, are the: most suitable, but do not drive to the venue on them or they will oil up. For ordinary road use there is nothing to compare with K.L.G. plugs, type G2.

As regards oil for speed work, Speedwell White Ideal or Wakefield Castrol R are the best.

Scrap the entire exhaust valve lifter assembly, and instead fit a magneto cut-out.

Balance Your Wheels.

Do not forget to see that the road wheel bearings are properly adjusted and locked, and also that the wheels spin freely. Correctly balance the road wheels by weighting the rim with a mass equal in weight to the heaviest part of the rim, so that the wheels, when set spinning, will come to vest at any point without oscillating.

Grease the leaves of the frame springs, and bind tightly with whip cord.

Fit a saddle lower than standard, such as Brooks B225.

See that the chain is in good condition, clean, well lubricated, and at the right tension.

If competing in a hill-climb adopt the following procedure: Get the engine thoroughly warmed up and bring your machine to the starting line. About five seconds before the word "Go," engage your bottom gear, keeping the machine stationary with the engine running gently by holding the clutch lever.

When the starter counts “three, two, one, go,” at the word three slam the throttle wide open. As he says "go," release the clutch lever completely letting the clutch fly in. The machine will plunge all over the road for few yards, therefore keep your feet dangling ready to give a dig one side or the other while you fight with the machine to get it straight.

Then, pick up your feet and, when engine is revving all out on bottom speed, slip the clutch and Snick the gear lever into second. Third and fourth speeds are engaged in a similar manner, the change not being made until the engine is really screaming on the particular gear in use. The throttle is not touched from start to finish, being left wide open until the finishing line is crossed. When changing gear in a hill climb, not more than half a second should elapse when changing up from the moment the clutch is slipped until it is fully home on the next gear.

Do not attempt the start with the engine howling by dropping the clutch lever until you have practised it in private, or you will find yourself in the ditch.

When descending the hill between classes do so with the gear lever in neutral, and the engine stationary, or you will promptly oil up your F12s.

Before concluding do not drill holes in the pistons, but you may leave off the middle piston ring. In fact, for speed work it is better to do so. In following out the tuning hints given, exercise the greatest care. Do not attempt it at all unless you know what you are about.

From "Motor Cycling" - August 17, 1921